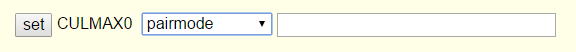

Having installed the new thermostat as detailed in the last post it is working fine as a standalone device, but the configuration in FHEM is needed to get the value out.

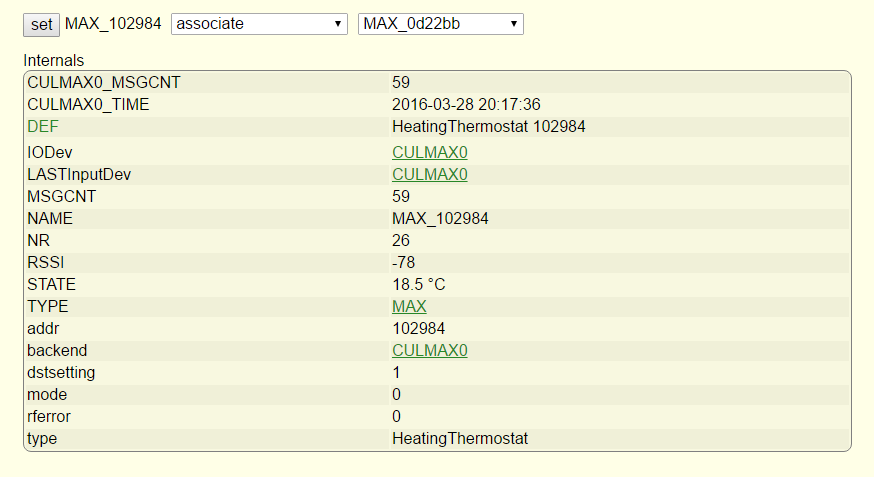

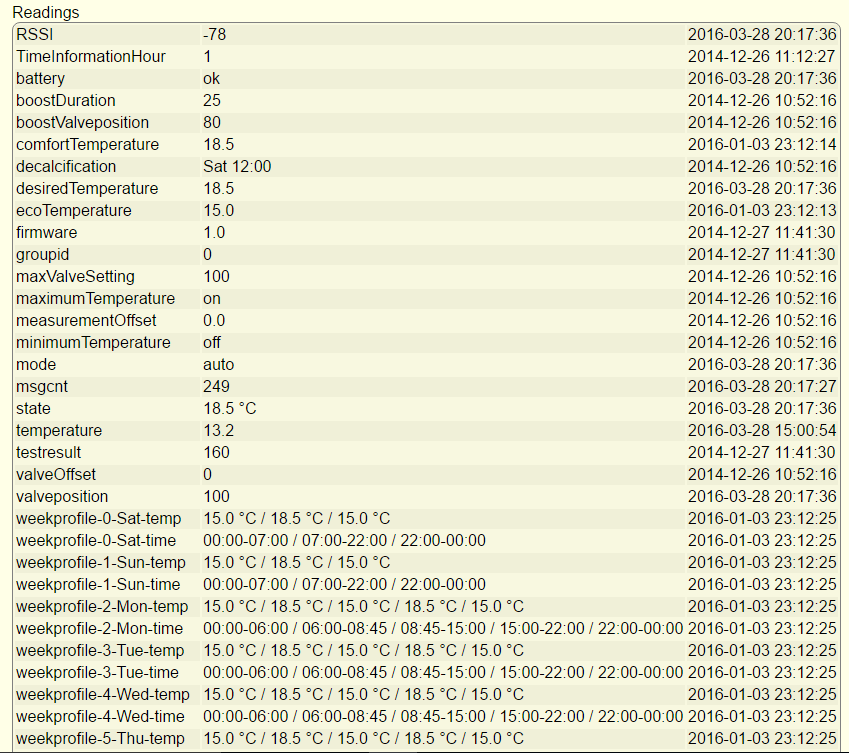

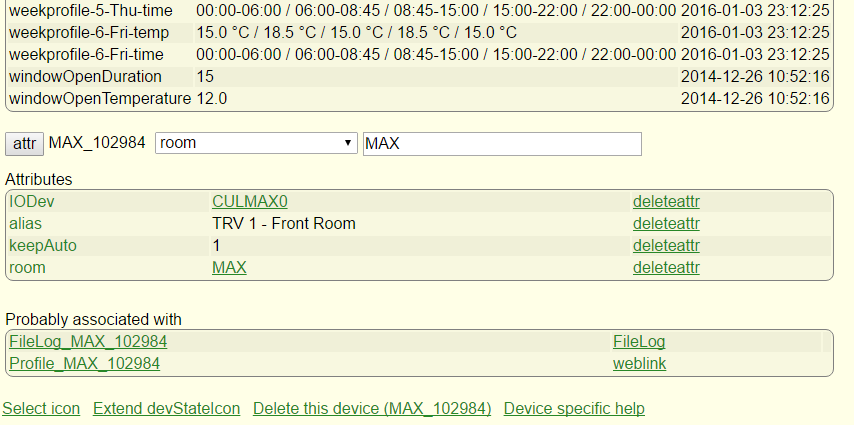

I’m always impressed by the amount of information you can get out of simple devices and this is no exception:

There are also loads of various readings you can get out as well, including a regular temperature reading which is great for monitoring:

You can also set almost any of the parameters, including the weekly profile and various other things.

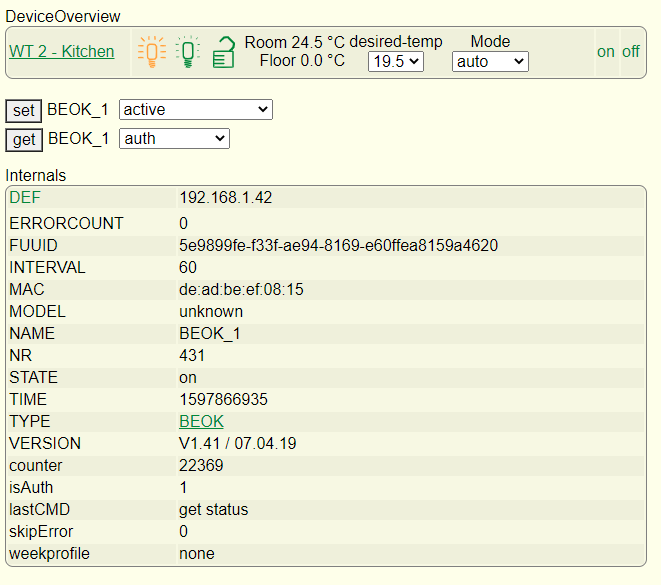

What I needed to find was a way of stopping the heating from running when the back door is open. When the cat goes out the air temperature in the kitchen drops rapidly and it is pointless to run the heating until she comes back in.

There are a number of possibles, one of the most obvious is a ‘frost protection’ mode which many thermostats have and although there is a setting for this it’s not mentioned in the manual and doesn’t actually seem to do anything. I could actually have simply switched the thermostat off completely (which I tested and worked well) although this felt a bit over the top and would stop the temperature monitoring.

I settled on switching between manual and automatic modes, with the manual setpoint set fairly low (around 15 degrees). So when the door is open the setpoint drops and the heating switches off. You can see evidence of this in the green line on the graph above.

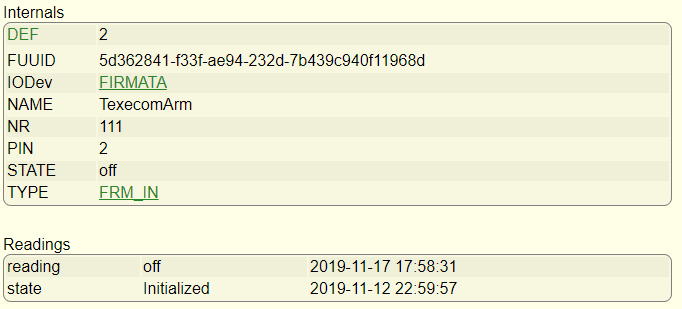

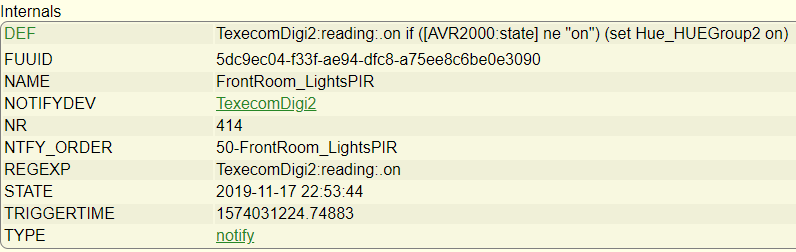

This is done in FHEM using notify events and some simple commands. It is simply a matter of ‘set BEOK_1 mode auto’ or ‘set BEOK_1 mode manual’ in response the event. This is done simply in FHEM using ‘notify’ events, one for the door opening another for the door closing:

To define this in FHEM I used the following:

define HeatingBackDoorClosed notify TexecomDigi4:reading:.off set BEOK_1 mode auto

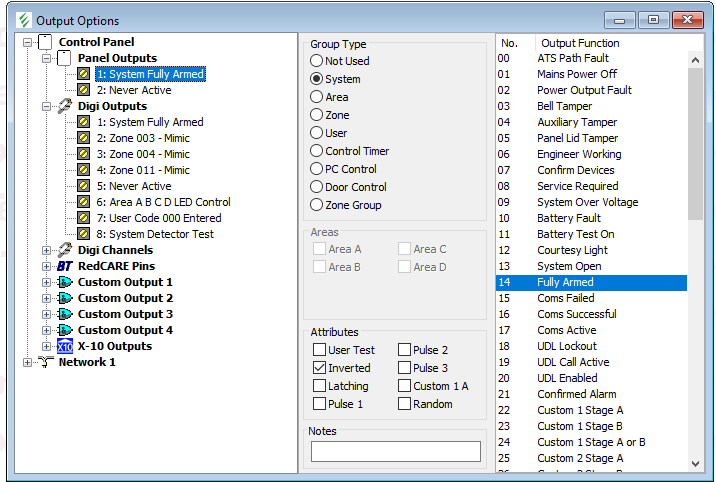

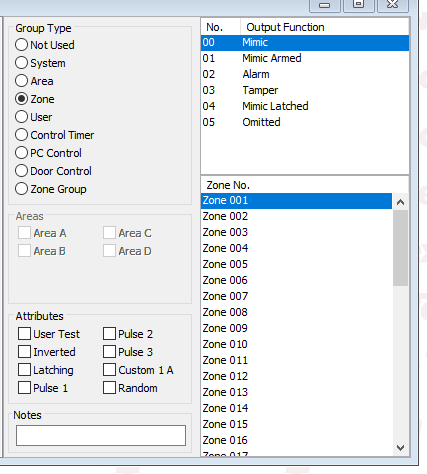

‘TexecomDigi4’ refers to the digital output, which is on when the door is open and off when closed. So whenever the door is closed, the trigger of the Digi4 to ‘off’ creates an event which sets the thermostat back to automatic mode. A similar one is in place to handle the door opening events.

I was pleased to find that this worked first time, and even with repeated and rapid opening and closing it doesn’t go out of sync. It has been far too warm lately for the heating to come on anyway and the cat has enjoyed long days in the garden but this is likely to change as we get into the Autumn.

So now I need to think of a few more use cases… and there are a lot of Texecom goodies to go at still.